July 31, 2012 feature

Roll-to-roll process prints thousands of cheap, flexible memory elements

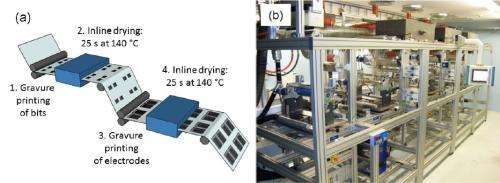

(�鶹��Ժ) -- In an attempt to lower the cost of making flexible write-once-read-many (WORM) memory devices, a team of researchers from Finland has developed a fabrication process that can mass-print thousands of these memories on a flexible substrate. Since they cannot be rewritten, WORM memories are particularly useful for tamper-proof applications, such as electronic voting and storing medical records.

The researchers, Jaakko Leppäniemi, Tomi Mattila, Terho Kololuoma, Mika Suhonen, and Ari Alastalo at the VTT Technical Research Centre of Finland, have published their paper on the WORM memory printing process in a recent issue of Nanotechnology.

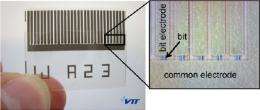

The WORM memory is a resistive memory in which data is written using a high-resistive ‘0’ state and a low-resistive ‘1’ state. Readout can be performed with a device that measures the different resistances by physical contact or capacitively by sweeping over the memory without making contact.

To realize a resistive WORM memory, the researchers prepared bits out of a silver nanopaste mixture that combines the advantages of two different commercial inks by Advanced Nano Products Ltd. One of the inks, called DGP, has the advantage of being writable with moderate electrical power, but has the disadvantage of instability due to the high-resistive ‘0’ state losing resistance. The second ink, called DGH, has the opposite properties: it requires a high electrical power for writing but has improved long-term stability. Although neither ink by itself is optimal for making memory bits, the researchers found that combining them offers the best of both worlds: moderate electrical power for writing and good long-term stability.

When combined, the two inks form a self-organized network, which allows the researchers to tune the initial conductivity and ‘0’ state resistance of the bits. The researchers could control the resistance by controlling how sintered and close together the nanoparticles are: resistance is high when the particles are unsintered and well separated, but decreases when the particles sinter and coalesce. To control the inter-particle distance, the researchers employed nanoparticles encapsulated with ligands to prevent agglomeration and create the high-resistive ‘0’ state. To decrease the resistance, and thus switch from the ‘0’ state to the ‘1’ state, the researchers removed the encapsulation by heating with electrical current. The heat melts the ligand, which allows the unencapsulated particles to coalesce and sinter, where they achieve higher conductivity and lower resistance.

In this way, the technique allows for selectively and irreversibly modifying the resistance of the bits, enabling a WORM memory function. As the scientists explained, such a memory has important advantages for real-world use.

“The advantage of the memory lies in the processability,” Leppäniemi told �鶹��Ժ. “The memories can be printed with high-throughput methods and the bit properties can be tailored by changing the composition of the bit ink. Also, the resistive memory provides simple, non-destructive readout when compared, for example, to printable ferroelectric random access memories.”

In terms of stability, the researchers observed the onset of a slow decline in the resistance after being stored for four months in the dark with a desiccant at ambient conditions. The decline resulted from the less-stable ‘0’ state due to self-sintering, which decreased its resistance. However, even after the 19 months of monitoring time, the researchers described the bits as maintaining a good ‘0’ state stability. In contrast, when exposed to a high temperature of 85 °C (185 °F) and a high relative humidity of 85%, the resistance underwent a rapid drop in less than three hours.

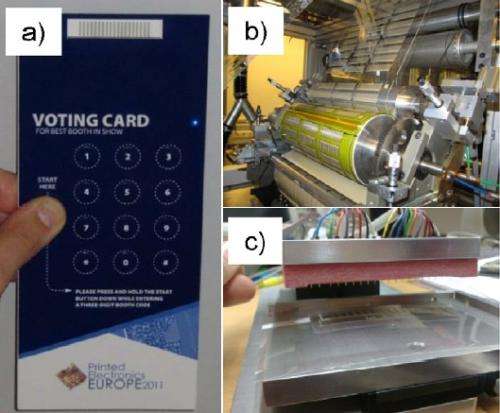

To demonstrate a simple application of the WORM memory, the researchers, together with Stora Enso Oyj, manufactured 1,000 electrical questionnaire cards for the Printed Electronics Europe 2011 conference that attendees used to vote for the best booth at the conference. A flexible printed battery supplied the small write voltage (less than 10 volts), and an LED inside the card indicated the successful push of a button. The questionnaire cards represent just one possible use of the WORM memory, which the researchers hope to further improve in the future.

“The goal is to provide printed memory addressing logic and reach higher bit amounts,” Leppäniemi said. “Also, improving the long-term stability via proper encapsulation requires further attention.”

More information: Jaakko Leppäniemi, et al. “Roll-to-roll printed resistive WORM memory on a flexible substrate.” Nanotechnology 23 (2012) 305204 (12pp).

Journal information: Nanotechnology

Copyright 2012 �鶹��Ժ

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of �鶹��ԺOrg.com.