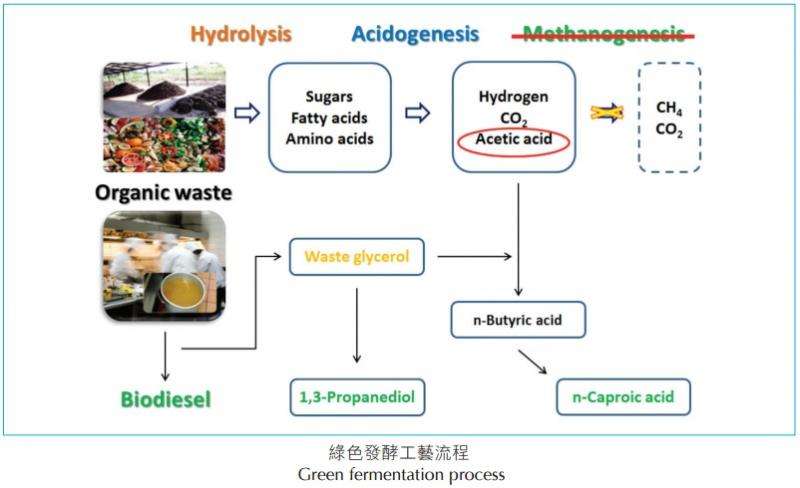

Green fermentation process from waste feedstock to high value chemicals

Researchers in Hong Kong have developed a novel anaerobic undefined mixed culture fermentation process to produce high value chemicals from glycerol and volatile fatty acids in waste water.

Glycerol is a low value by-product in bio-diesel production. The production ratio of glycerol to bio-diesel is 1:10. Researchers at The Hong Kong Polytechnic University (HK PolyU) developed a novel anaerobic undefined mixed culture fermentation process to produce high value chemicals from glycerol and volatile fatty acids in waste water.

In the fermentation process, glycerol provide electron to convert fatty acids into n-Caproic acid, which is a basic industrial chemical widely used in artificial flavour, medicine, and lubricant manufacturing. Its energy density is 700 times higher than that of gas methane, and is 1.2 times that of liquid ethanol. That its water solubility (1.1 g/100 mL at 20 °C) is low makes it easily recovered by distillation. At the same time, another high value chermical 1,3-propanediol is produced, which is used in polymers manufacture.

In addition to converting wastes into high value raw materials, this green fermentation process can also be used to treat wastewater.

Special Features and Advantages

- A value-added chemicals production from waste feedstock

- The anaerobic undefined mixed culture system reduces the costs and energy for sterilization and aeration

- Product recovery is simple and cost-efficient

Applications

- This green fermentation process can be applied to municipal or industrial wastewater treatment process for resource recovery

- This process can also solve the byproduct treatment and disposal problem

Provided by ResearchSEA