November 6, 2023 feature

Hydrogel-assisted microfluidic spinning of stretchable fibers via fluidic and interfacial self-adaptation

Thamarasee Jeewandara

contributing writer

Stretchable polymeric fibers have significant impact, although their production requires rigorous environmental methods and resource consumption. The process is challenging for elastic polymers with reduced spinnability and high performance, such as silicones, polydimethylsiloxane, and ecoflex.

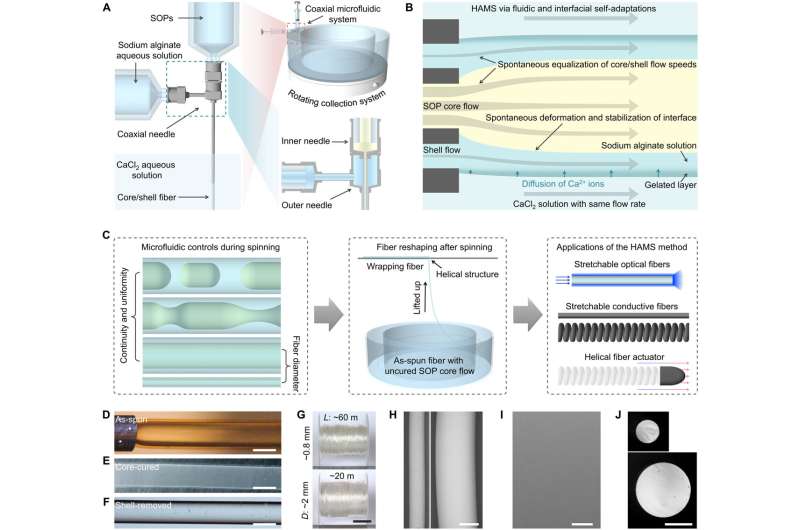

Guoxu Zhao and a team of scientists in medical engineering, materials science, and life sciences in China, have presented a hydrogel-assisted microfluidic spinning method to address such challenges, which they accomplished by encapsulating pre-polymers within long, protective, and sacrificial hydrogel fibers.

The research has been in the journal Science Advances.

They designed simple apparatuses and regulated the fluidic and interfacial self-adaptations of oil/water flows to successfully produce fibers with a widely regulated diameter, notable length, and high quality. The method allowed for easy, effective, reshaping of helical fibers for exceptional stretchability, and mechanical regulation.

The fibers have potential applications as textile components and optoelectronic devices. The method provides a powerful path to mass-produce high quality stretchable fibers.

Stretchable polymers

Intrinsically stretchable fibers have widespread applications when compared with non-stretchable fibers, where stretchable fibers can retain their functions under mechanical dynamics to realize specific uses. Stretchable polymers can be incorporated to develop biomaterials and bioelectronics with increasing attention obtained for their capacity to .

However, the large-scale fabrication and use of materials are limiting within the spinnable elastic polymers, including polyurethane and . The materials can be processed by using traditional spinning methods.

Such spinnable polymers can be prepared into melts or solutions that are shaped like fiber-like fluids. Alginate hydrogels, thus formed between alginate molecules and cations, are in wide use for their biocompatibility, biodegradability, and .

To realize a spinning technique suited for slow cuing and oil-phase prepolymers, the team developed a microfluidic spinning system to encapsulate the prepolymers with alginate hydrogel fibers, and studied the related mechanisms and influences.

The hydrogel-assisted microfluidic spinning (HAMS) method

A simple, effective, and scalable hydrogel-assisted microfluidic spinning method can, under ambient temperature in the absence of an organic solvent, produce oil-phase prepolymers-based stretchable fibers. The prepolymers and sodium alginate aqueous solution can be co-extruded into a calcium chloride aqueous solution to create a hydrogel fiber/shell. The HAMS method can realize fiber geometries to reshape the production of helical fibers. The application potential of the method is shown by producing fibers from different prepolymers to investigate their versatility.

Fiber development with different viscosities

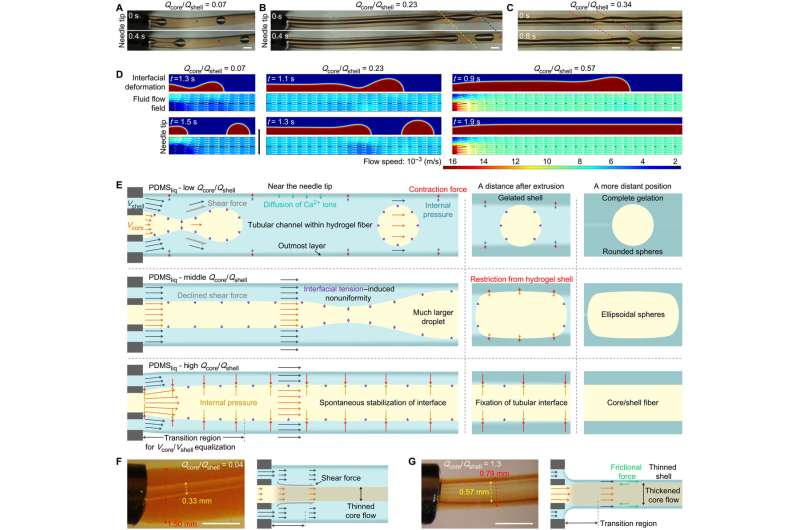

The research team studied the influence of flow viscosity on fiber spinning by using liquid polydimethyl siloxane (PDMS) and thixotropic PDMS, which responded differently to the flow rates.

The scientists explored the applicability of the HAMS method by using Ecoflex, neutral silicone, and carbon nanotube-composite PDMS. The HAMS method holds great promise to produce oil-phase prepolymers based stretchable fibers. The scientists further explored how the fluidic and interfacial self-adaptation mediated the oil phase spinning mechanisms. Spun fibers developed via the HAMS method are a protective and flexible hydrogel for favorable mechanical properties and functions.

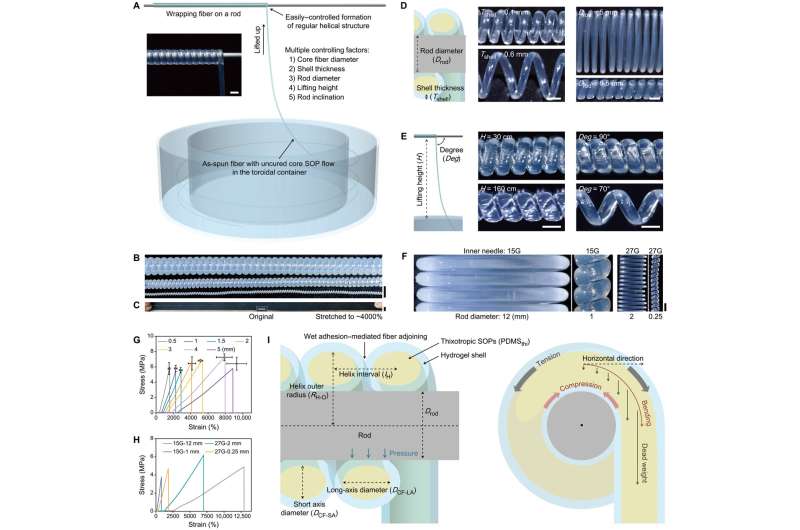

The team reshaped helical structures by lifting air spin fibers from calcium chloride solution and wrapping onto rod templates to form helical fibers with uniform structures, a wide size range and excellent stability. The method offers a widely regulated approach to create extremely stretchable helical fibers. With these basic principles, regular helical structures can be easily and effectively wrapped to produce helical fibers.

Polymer characteristics

Zhao and colleagues assessed the role of prepolymer rheology mixtures with different volume ratios of PDMS and tuned the needle sizes to indicate the possibility of realizing the hydrogel-assisted microfluidic spinning method. While this process of encapsulating low viscosity oils with hydrogel fibers are , it is important to study the mechanisms and optimizing strategies of the hydrogel-assisted microfluidic spinning method.

They also studied the wearable sensing performance of PDMS optical fibers to create finger bending and touching signals suited to input and transmit Morse information; as wearable mechanical sensors.

Zhao and colleagues further investigated the mechanical sensing performance of the fibers, where the resistance precisely responded to cyclical stretching with different strains. The results highlighted the application potential of the method to produce straight, fiber-based wearable strain sensors and ultra-stretchable conductors.

![Application demonstrations of stretchable fibers fabricated via HAMS method. (A) Photographs showing the magnetically driven elongation of a magnetic-modified helical PDMSthi fiber within a vessel-like channel [a polyvinyl chloride (PVC) tube as model] to reach a target (a magnet as model) and its spring back after removing the magnetic field (scale bar, 5 mm). (B) Photograph of a 1-m-long PDMSliq fiber in transmitting red, green, and blue lights (scale bar, 2 cm). (C) Photograph of this PDMSliq fiber in transmitting red light under bending (scale bar, 2 cm). (D) Influence of PDMSliq fiber length on its light transmission in transmitting red, green, and blue lights. (E) Light transmission of a PDMSliq fiber during a 1000-times 100%-strain cyclical stretching process. (F to I) Monitoring of (F) finger bending, (G) finger pressing, (H) finger pressing–inputted Morse information, and (I) wrist pulses based on the light transmission of a PDMSliq fiber. The average pattern shows the systolic peak (PS), tidal wave (PT), and diastolic peak (PD) of wrist pulses. (J) SEM images of straight and helical CNT/PDMSliq fibers. (K) Resistance variation (△R/R0) curves and tensile curves of straight and helical CNT/PDMSliq fibers during a stretching-until-break process. (L) △R/R0 curves of a straight CNT/PDMSliq fiber during cyclical stretching processes with different strains. (M) Monitoring of finger bending using a straight CNT/PDMSliq fiber. (N) Wirelessly monitoring of finger bending by combining a CNT/PDMSliq fiber with a Bluetooth unit and phone application, and (O) the wirelessly monitoring result on finger bending. Credit: Science Advances, doi:10.1126/sciadv.adj5407 Hydrogel-assisted microfluidic spinning of stretchable fibers via fluidic and interfacial self-adaptation.](https://scx1.b-cdn.net/csz/news/800a/2023/hydrogel-assisted-micr-3.jpg)

Outlook

In this way, Guoxu Zhao and team developed a hydrogel-assisted microfluidic spinning method to produce slow-cuing oil-phase prepolymers, based on stretchable fibers. This hydrogel-assisted microfluidic spinning method can be conducted without melting or dissolving polymers via a high consumption of energy or organic solvent, as an economically and environmentally favorable strategy. By using fast-curing prepolymers alongside two component syringe and mixing head, the curing process can be accelerated.

Written for you by our author —this article is the result of careful human work. We rely on readers like you to keep independent science journalism alive. If this reporting matters to you, please consider a (especially monthly). You'll get an ad-free account as a thank-you.

More information: Guoxu Zhao et al, Hydrogel-assisted microfluidic spinning of stretchable fibers via fluidic and interfacial self-adaptations, Science Advances (2023).

Journal information: Science Advances

© 2023 Science X Network