Research team develops a more durable coating against ice

Ice-repellent coatings have been around for some time, but until now they have been very sensitive and detach quite quickly from the surfaces they are meant to protect. A research team led by Anna Maria Coclite and Gabriel Hernández RodrÃguez from the Institute of Solid State Â鶹ÒùÔºics at Graz University of Technology (TU Graz) has now succeeded in remedying this shortcoming. They have developed a highly ice-repellent coating that adheres to a wide variety of materials and is very resistant to abrasion.

The team's paper is in the journal ACS Applied Materials & Interfaces.

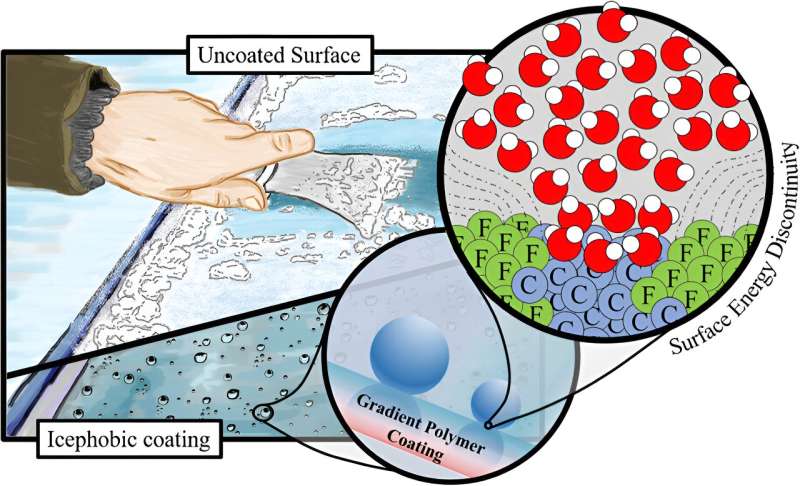

The researchers achieved this progress by using a manufacturing technology called initiated chemical vapor deposition (iCVD). This makes it possible for a strongly adhesive primer material to gradually transition into the ice-repellent compound.

This stepless transition is achieved by applying the two materials as a changing gas mixture to the surface to be coated. Initially, the gas mixture consists purely of the primer material, but the proportion of the ice-repellent material is continuously increased during application, from 0 to 100%. The result is a coating with a strongly adhesive underside and a top side that prevents ice crystals from sticking.

-

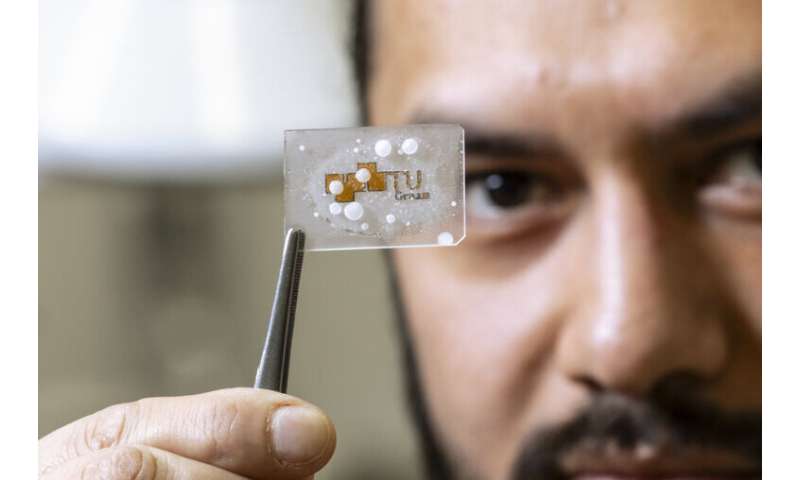

The ice-repellent coating is wafer-thin. For their experiments, Anna Maria Coclite and Gabriel Hernández RodrÃguez (pictured here) applied it in thicknesses from 300 to 500 nanometers. Credit: Lunghammer—TU Graz -

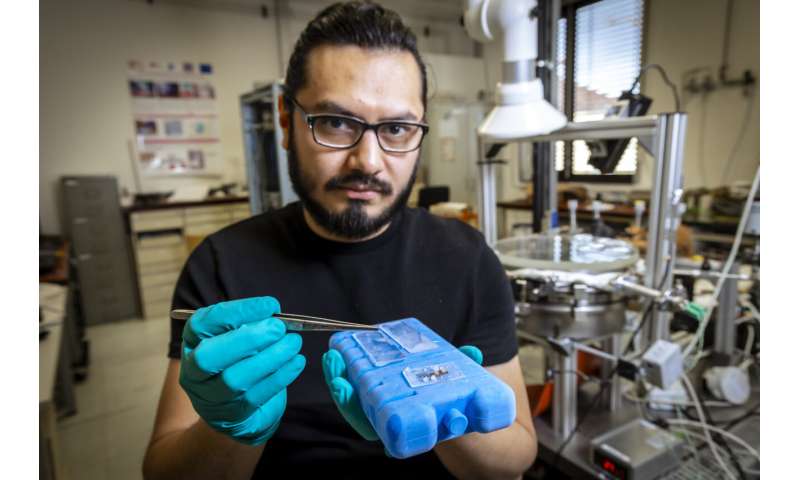

A wide range of applications are conceivable for this new type of coating, for example in the aviation industry (shown in the photo: Gabriel Hernández RodrÃguez with deep-frozen samples of coated acrylic glass). Credit: Lunghammer—TU Graz

Random alignment of the molecules creates an ice-repellent effect

During their experiments, Coclite and Hernández RodrÃguez discovered the basis of the coating's ice-repellent property.

"The ice-repellent material consists of elongated molecules that adhere to the primer in a vertical or horizontal orientation," explains Hernández RodrÃguez. "The thicker we applied the material, the more random the alternation between vertical and horizontal molecules became. And the more random the arrangement at the surface, the greater the ice-repellent effect." This mechanism was previously unknown.

A wide range of applications are conceivable for this new type of coating, for example in the aviation industry. "Such a coating could speed up the de-icing of aircraft and use less antifreeze," says Coclite. Sensors exposed to the weather that are disturbed by ice could also benefit from such coating.

More information: Gabriel Hernández RodrÃguez et al, Icephobic Gradient Polymer Coatings Deposited via iCVD: A Novel Approach for Icing Control and Mitigation, ACS Applied Materials & Interfaces (2024).

Provided by Graz University of Technology