Nanoscale Dimensioning Is Fast, Cheap with New Optical Technique

(¬ť∂Ļ“ý‘ļOrg.com) -- A novel technique under development at the National Institute of Standards and Technology uses a relatively inexpensive optical microscope to quickly and cheaply analyze nanoscale dimensions with nanoscale measurement sensitivity. Termed ‚ÄúThrough-focus Scanning Optical Microscope‚ÄĚ (TSOM) imaging, the technique has potential applications in nanomanufacturing, semiconductor process control and biotechnology.

Optical microscopes are not widely considered for checking nanoscale (below 100 nanometers) dimensions because of the limitation imposed by wavelength of light‚ÄĒyou can‚Äôt get a precise image with a probe three times the object‚Äôs size. NIST researcher Ravikiran Attota gets around this, paradoxically, by considering lots of ‚Äúbad‚ÄĚ (out-of-focus) images.

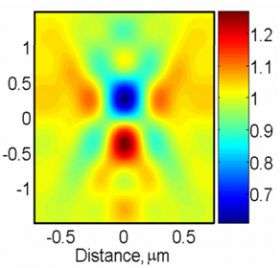

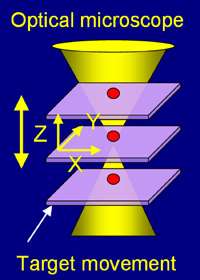

‚ÄúThis imaging uses a set of blurry, out-of-focus optical images for nanometer dimensional measurement sensitivity,‚ÄĚ he says. Instead of repeatedly focusing on a sample to acquire one best image, the new technique captures a series of images with an optical microscope at different focal positions and stacks them one on top of the other to create the TSOM image. A computer program Attota developed analyzes the image.

While Attota believes this simple technique can be used in a variety of applications, he has worked with two. The TSOM image can compare two nanoscale objects such as silicon lines on an integrated circuit. The software ‚Äúsubtracts‚ÄĚ one image from the other. This enables sensitivity to dimensional differences at the nanoscale‚ÄĒline height, width or side-wall angle. Each type of difference generates a distinct signal.

TSOM has also been theoretically evaluated in another quality control application. Medical researchers are studying the use of gold nanoparticles to deliver advanced pharmaceuticals to specific locations within the human body. Perfect size will be critical. To address this application, a TSOM image of a gold nanoparticle can be taken and compared to a library of simulated images to obtain ‚Äúbest-match‚ÄĚ images with the intent of determining if each nanoparticle passes or fails.

This new imaging technology requires a research-quality optical microscope, a camera and a microscope stage that can move at preset distances. ‚ÄúThe setup is easily under $50,000, which is much less expensive than electron or probe microscopes currently used for measuring materials at the nanoscale,‚ÄĚ Attota explains. ‚ÄúThis method is another approach to extend the range of optical microscopy from microscale to nanoscale dimensional analysis.‚ÄĚ So far, sensitivity to a 3 nm difference in line widths has been demonstrated in the laboratory.

Citation: R. Attota, T.A. Germer and R.M. Silver. Through-focus scanning-optical-microscope imaging method for nanoscale dimensional analysis, Optics Letters 33, 1990 (2008).

Provided by NIST