3D printing technology for tissue: Researchers combine hydrogels and fibers

In the latest study by Prof. Dr. Leonid Ionov, Professor of Biofabrication, and his team at the University of Bayreuth, various types of hydrogels were extensively tested for the 3D printing of tissues. A hydrogel is a water-retaining and also water-insoluble polymer. In addition, the cell containingÔÇôhydrogels, also known as bioink, are combined with fibers to create a composite material.

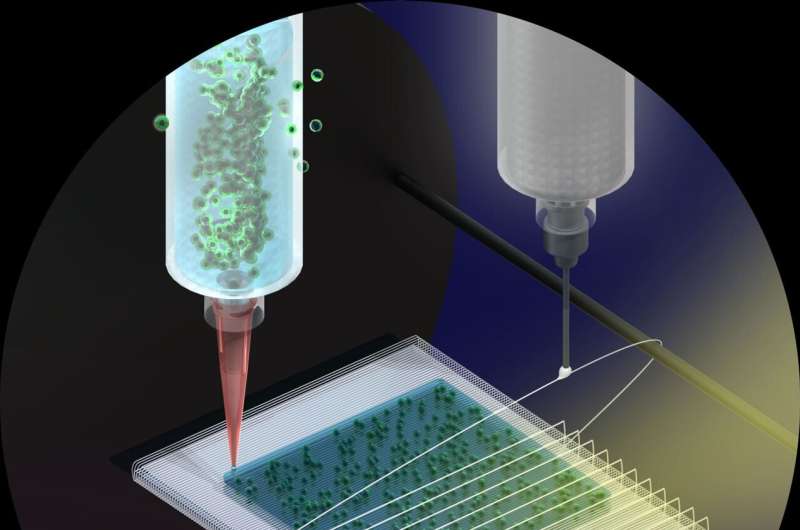

This is achieved by using 3D (bio) printing with an integrated touch-spinning process. Touch spinning is a scalable process for producing fibers from a polymer solution or melt. The Bayreuth scientists have now combined 3D (bio) printing technology with touch-spinning technology in a single device for the first time.

"The insights gained in this study are of great importance for the production of tissues and in particular tissues with fibrous structures and uniaxial alignment of cells such as connective and muscle tissue," explains Prof. Dr. Ionov.

In their article recently in the journal Advanced Healthcare Materials, Prof. Dr. Ionov, along with Bayreuth researchers Prof. Dr. Dr. Elisabetta Ada Cavalcanti-Adam, Chair of Cellular Biomechanics, Waseem Kitana, Ph.D. student at the Chair of Biofabrication, and their colleague Dr. Victoria Levario-Diaz from the Max Planck Institute for Medical Research, report on a novel approach for the production of multilayer bioink fiber composites.

The Bayreuth scientists used various hydrogels in the experiments and compared their properties. Hydrogels have been widely used as scaffold materials in the fields of tissue engineering and biofabrication for decades. Tissue engineering is the umbrella term for the artificial production of biological tissues.

The combination of a hydrogel system with a fiber system reduces the processing requirements for hydrogels, such as cross-linking to improve their mechanical properties, as the mechanical properties of these composite materials are covered by the fiber system. In addition, the requirement for a low degree of cross-linking is advantageous for subsequent tissue formation.

"The hydrogel provides the cells with an aqueous environment that promotes the good functioning of the cells, while the fibers should control the orientation of the cells along the main direction of the fiber," says Prof. Dr. Ionov.

More information: Waseem Kitana et al, Biofabrication of Composite BioinkÔÇÉNanofiber Constructs: Effect of Rheological Properties of Bioinks on 3D (Bio)Printing and Cells Interaction with Aligned Touch Spun Nanofibers, Advanced Healthcare Materials (2023).

Provided by Bayreuth University